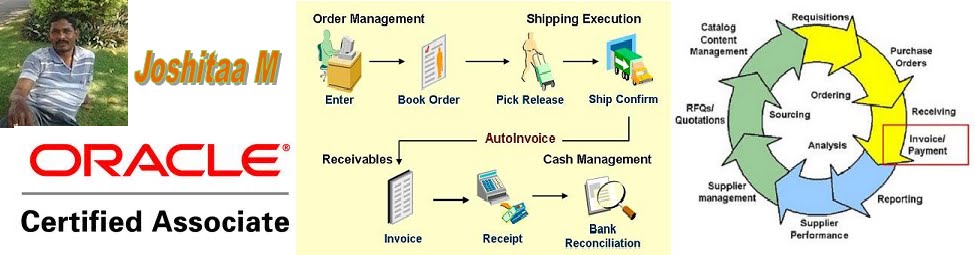

Internal requisitions provide the mechanism for

requesting and transferring material from inventory to other inventory

or expense locations. To use this functionality, you need to have

Purchasing, Order Management, Shipping Execution, and Inventory

installed. Internal Requisition (after suitable approval) will directly

result in the generation of a sales order in the Order Management system

through the Order Import process in Order Management

Setup Steps:

Step 1 - Creating the Item (Navigation: Items/Master Items)

a) On the Purchasing Tab - add a price if the item is to be used in iProcurement.

Uncheck the purchasing checkboxes, if the item is to ONLY be ordered from an internal source.

b) On the Order Management tab, and choose the attributes: Internal Ordered, Internal Orders Enabled & OE Transactable

c) Ensure that the item is assigned to both the Source and Destination Inventory Organizations

Step 2 - Create the Shipping Network (Navigation: Setup/Organizations/Shipping Networks)

a)Enter the Inventory Organization that will be the Source and the scope should be From or To Organizations

b)Choose the Transfer Type

Direct

- means that when the Internal Sales Order is shipped the receipt

process in the destination organization is done automatically

Intransit

- means that when the Internal Sales Order is shipped - the destination

inventory organization has to manually do the receiving process in

Purchasing

c)Choose Internal Order Required checkbox

Step 3 - Create the Location (Navigation: Setup/Organization/Locations)

Enter

a Location Name - for the Internal Location. This is the location that

is used as the Destination Location & will eventually be tied to a

customer

Step 4 - Conduct a Miscellaneous Receipt (Navigation: Transactions/Miscellaneous Transactions)

This

step is being done to satisfy the Internal Sales Order which is

created, as it ensures there will be ample quantity On Hand to perform

the shipping portion of the Internal Sales Order process.

a)Choose the Inventory Organization that will be the Source Inventory Organization

b)Enter 'Miscellaneous Receipt' - Choose 'Transaction Lines'

c) Enter the Item created and then a sub-inventory, quantity, etc

Step 5 - Create the Internal Customer - Assign the Location

(Navigation: Customers/Standard)

a) Enter the Internal Customer Name - Choose the Find Button

b) If it is a new customer - choose New from the dialog box that appears

c) In this form - choose Open and enter the address details

d) Move to the lower half of the form - enter a usage - of 'Ship To'

e) Followed by choosing the Open button in the lower right hand corner of the form

In the new form which opened - enter the basic information for Payment Terms, Salesperson, etc.

Important: In the Internal Block - choose the Location which was created in Step 3

This

association ties the customer to the location. Move to enter other

pertinent information such as price list, etc, save - Close this

SUB-FORM ONLY

It is also recommended to create a Bill To Usage record for the new customer.

Add a new record to the usage - and call this Bill To

Hit Open and enter any new information that pertains to the Bill To

Step 6 - Item Price (Navigation: Items/Master Items)

a) Query the item created in Step 1

b)

Choose "Tools/Item Costs" from the top text menu. The screen to follow

shows the item price that is used when creating the Internal

Requisition. This is how purchasing derives the price when creating the

Internal Requisition

This blog is to gather all Oracle Apps Professionals and their expertise to build a robust knowledge in Oracle Applications. This blog is not only for Oracle experts/professionals but also for beginners and who would like to pursue their career in Oracle Applications. I would like to invite all the Oracle Professionals for this blog to share their Oracle skills. Also, I would like to take this opportunity to wish success in all our endeavors.

Subscribe to:

Post Comments (Atom)

good

ReplyDelete